Sake Brewery Review – Clear Innovation at Tochigi’s Nishibori Shuzo

I was fascinated to learn from a recent Sake Lovers virtual brewery tour of Nishibori Brewery about how far a brewer will go in search of new techniques to further improve their sake quality. Let me share some of their unique innovations with respect to transparent acrylic fermentation tanks and unique sake aging techniques.

Brewery Background

Nishibori Brewery was founded in 1872 in the town of Oyama in Tochigi. The town had served as one of the official resting stations along the Nikko-kaido road connecting Edo (Tokyo) to the famous Nikko Toshogu Shrine (UNESCO World Heritage). This ancient road was properly established in the early 17th century for travelers to the Nikko temple and shrine mausoleum of the first shogun, Tokugawa Ieyasu. In addition to its historical significance, Oyama boasts an ample supply of high quality spring water originating from the nearby Nikko mountains. Medium-hard, the water is ideal for sake brewing, according to Tetsuya Nishibori the future and to be the sixth generation family kuramoto (owner). Since the former toji (brew master) retired, the brewing responsibility has been shared by Nishibori and his team, a move I suspect is nurturing more diversity and fueling their innovative ideas.

Consisting of 14 staff, the brewery produces about 500 koku (90,000 liters) of sake annually across 16 products. Built on Nanbu toji guild roots, the brewery interestingly leverages modern technologies to uphold their respected traditional brewing methods. During the tour, Nishibori pointed out some of their temperature and weighing equipment fed into smart phone apps to help in constantly watching over the progress of koji-making and fermentation processes.

〰️ In a gentle voice with his kind smile, Nishibori described his deep enthusiasm for some of his innovations.

Clear Thinking, Clean Sake

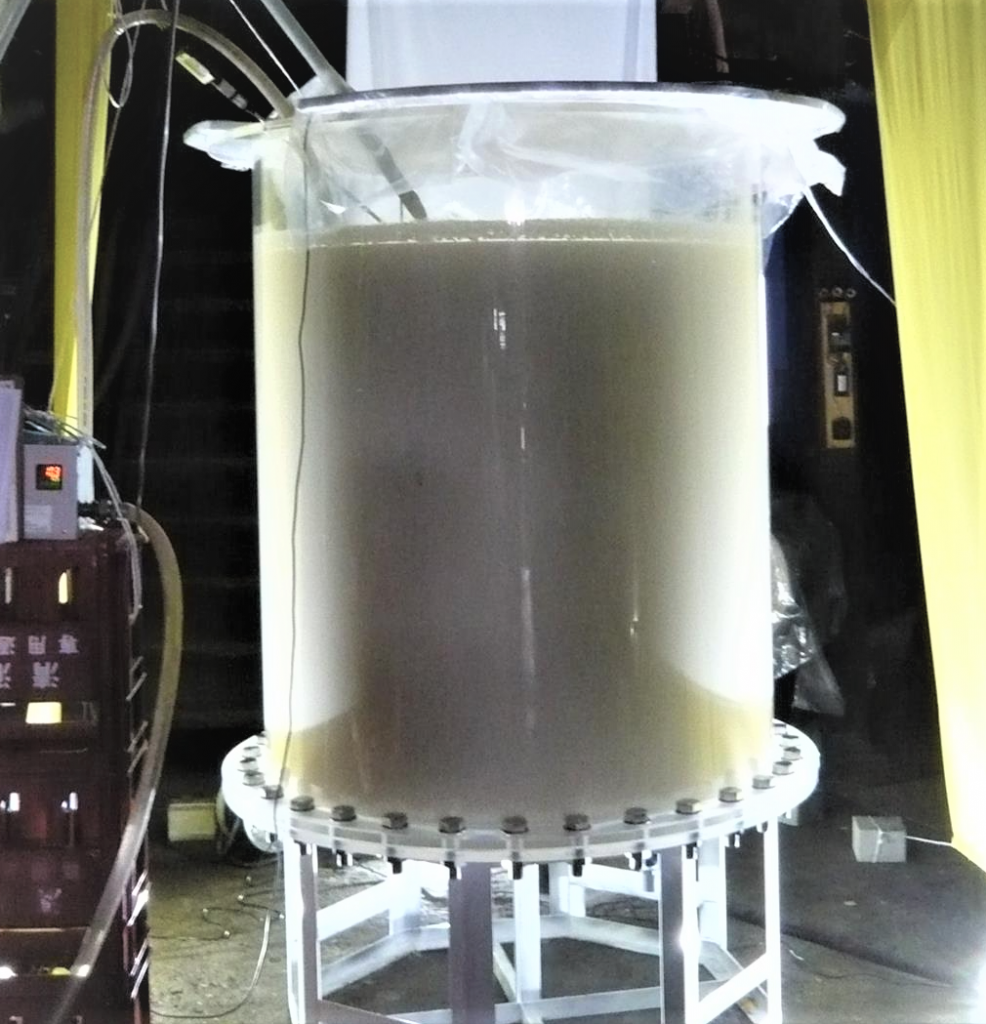

Welcome to not only Japan’s, but likely, the world’s first acrylic sake moromi (main fermentation mash) tank! I pondered on why make the tank transparent? Nishibori explained that brewers today are limited to a top-only view of fermentation tanks. A “see-through” tank offers better monitoring of what is going on inside the tank and provides the brewer with more information to ultimately improve the sake.

His groundbreaking idea, however, almost remained just an idea after his approaches were declined by traditional sake tank makers. Nishibori eventually found a Hiroshima-based aquarium tank maker to build his one and only 1,500 liter acrylic tank. The first batch made with the acrylic tank was in March 2017. Using a time lapse camera looking into the side of the tank, they could closely observe the microbial activity. From the movement of vertical and horizontal flows within the tank, which initially were very slow but later strengthened, the brewers could visibly confirm how well the fermentation was progressing. Nishibori further explained that brewers need to mix the moromi (kakimaze/kai-ire) using a long oar-like tool (kaibo) typically every morning and night to ensure the moromi activity was consistent throughout the tank. However, such intervention tends to increase zatsumi (astringencies or off-flavors) due to the pounding and squashing action on the koji and rice. Zatsumi is normally undesired. Mixing cannot be eliminated, but by monitoring the moromi flow profile and activity, the brewer can judge when mixing is unnecessary and thus minimize zatsumi. Mixing itself leads to increased oxidization that contributes to acidity which may not be desired.

A second benefit is having more efficient low temperature management of the moromi. While outer cooling jackets are typically used to cool moromi inside of steel tanks, brewers must continue mixing because the tank center remains warm and, as we learnt, mixing increases zatsumi. The acrylic tank on the other hand uses a stainless-steel cooling coil inserted directly into the tank which more effectively controls the moromi temperature with significantly less effort and resulting again in reduced zatsumi.

The third benefit is the availability of additional information to help the brewer make better judgements in what to adjust during the fermentation. Nishibori explained that visible layers, or liquid clouds, having different shades of white will form and each tells a story of how advanced the saccharification (ie. rice dissolving and being converted to glucose) is proceeding. The more translucent color indicating more advanced saccharification. At the same time (multiple parallel fermentation), as the yeast is eating up the glucose to produce alcohol, carbon dioxide bubbles will be released. While the size of these bubbles will vary depending upon the yeast strain used, the relative size of the bubbles will reflect how strong the alcohol conversion is progressing. Too small a bubble size can indicate areas suffering from lack of oxygen for the yeast to grow and timely adjustments can be taken by the brewer.

The acrylic tank was not a cheap investment. It cost 3-4 times more than a regular steel tank. In order to help recoup the cost of the investment, the tank is primarily used for high end junmai daiginjo where the sake could retail from 3,100 yen for a 720ml bottle. According to Nishibori, the acrylic tank sakes offer a much cleaner taste attributed to the reduced zatsumi as well as the measurable reduction in acidity. His patent application on clear tank brewing was successfully approved in 2019.

〰️ Well, I thought the acrylic tank was pretty impressive, but Nishibori didn’t stop there.

Putting Some Light On Yeast

While it is well known in the industry that combining sake with light is taboo ( 〰️ we keep our sake stored in dark cool places, correct?), Nishibori further stretches the boundaries in search of light colors which may improve his sake. A few Japanese and foreign research publications exist on the subject of how visible light wavelengths affect microbial activity during fermentations. Based upon one research finding that yellow light increased yeast activity, Nishibori reasoned that stronger energy wavelengths of blue and violet colors could further restrain the activity of koji bacteria and yeast microorganisms during the cool brewing for daiginjo sake. With a little financial help from cloud funding, in 2020 Nishibori set up four large blue LED light stands around the acrylic tank for the 25 day duration of the fermentation. Apparently, blue light won’t increase the temperature of the moromi.

The outcome? Nishibori explained he was able to produce better well-rounded and mellow flavors and he could also produce pronounced daiginjo aromas from a lower ginjo specification batch.

From March, Nishibori will next experiment using red colored LEDs which have a longer wavelength. He reasons that while the microbial activity may be higher, he is aiming for a drier sake with a little more acidity. The moromi will end in April for fukuro-shibori (bag dripping) filtering, pasteurization (hire), and bottled straight away (bin-zume) for shipping.

〰️ Wow, I would like to get a choko or two of that once it is available – for the benefit of research of course!

Good Vibes, Good Aging

I have read of interesting places like dams, caves and snow where brewers will store sake for long-term aging. Nishibori took aging not just one, but two steps further.

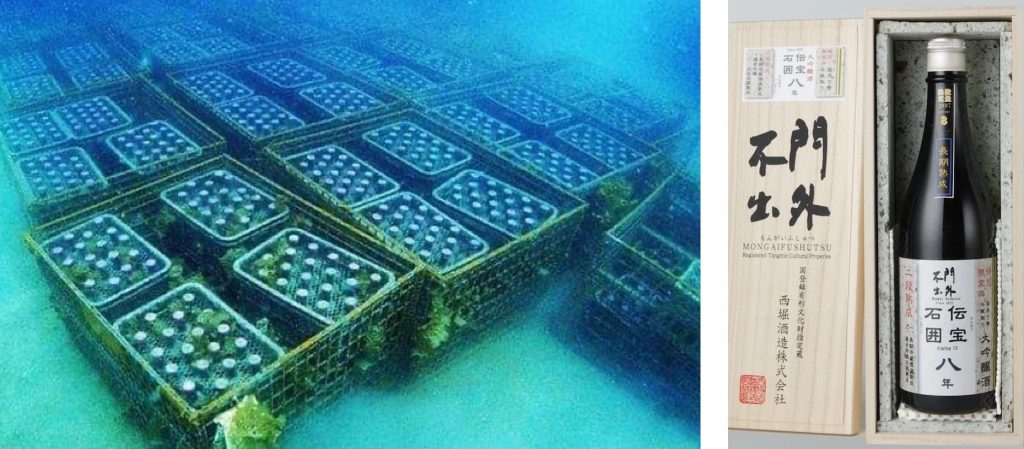

Firstly, while this is practiced today in the wine industry and to a rare extent with sake, Nishibori in 2019 had crates of ishoubin sake bottles (1.8 liter) placed at depths of 15 meters in the sea near Ito in Shizuoka Prefecture in order to experience the effects of under-sea aging. He explained the sea motion at this depth provides optimal vibrations to promote alcohol aging – supposedly by molecular seismic movements. He observed how six months exposure to the natural vibrations of the sea had the comparable effect of two years of typical land-based storage. Nishibori further explained similar aging outcomes have been reported from music vibrations as well. While this was an interesting experiment, they have no immediate plans yet to return to the sea bottom.

〰️ Maybe music will be next?

Let’s Rock on

The second aging innovation is interesting because it seems to encourage consumers to age their sake at home, like many would with wine. Sake that is firstly aged within the brewery in a 2°C kept environment for 3, 8, and 12 years is placed in a zeolite rock lined box (Denpo-ishigakoi 伝宝石囲) for purchasers to take home for “second-stage” aging. This product is already in its fifth year.

Tochigi is home to large resources of natural Zeolite (Oya-ishi) stone, a porous rock more familiarly used in water purification. Zeolite is said to have “healing and aging benefits” due to its natural emissions of negative ions and ultra-infrared light. Nishibori explains it has been used locally for a considerable number of years for maturing cheeses and meats, so why not try it with sake?

〰️ Does anyone have any kryptonite?

Nishibori has other experiments in mind. He ended our conversation with a final remark “I have also heard that electricity can also help in aging sake!”.

Nishibori Shuzo

Awanomiya 1452, Oyama-shi, Tochigi Prefecture

https://nishiborisyuzo.com/en/ (English content available)

Interesting side facts:

🖊️ While most sales are within Tochigi Prefecture, the brewery is exporting in small shipments to Australia, Hong Kong, Italy, Singapore, Taiwan, and US.

🖊️ Brewery’s existing buildings were built between 1850 to 1925. Four buildings became registered as tangible cultural properties in 1995.

🖊️ Nishibori in 2017, using 4 stage fermentation, was the first brewery to release junmai sake made 100 percent from ancient rice. While red and yellow ancient rice is typically produced for table rice use, the rice must pass inspection and be 3rd grade or above in order to legally label the sake as junmai. The ancient rice Nishibori uses is more expensive than Yamadanishiki. Other breweries typically blend ancient rice with other inspected rice for junmai.

🖊️ See Anat Parness’ review on Nishibori’s I-My-Me umeshu product at Sake Geek here.